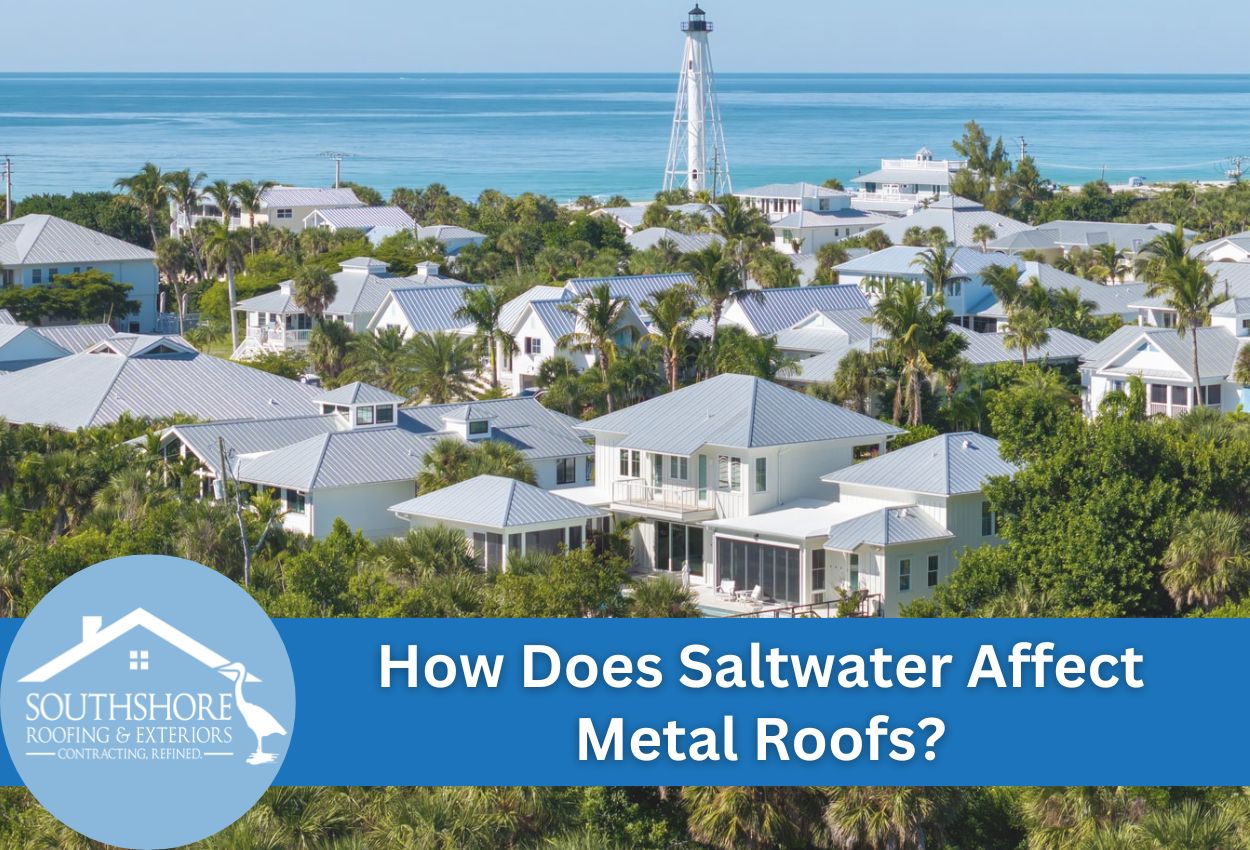

Metal roofs are a great option for homeowners along Tampa’s coastline and other seaside areas, but they still may not be completely resistant to corrosion that can be caused by the metal’s proximity to saltwater. Saltwater exposure is one of the most aggressive environmental factors that can damage metal roofs, potentially shortening their lifespan if proper precautions aren’t taken.

When salt particles settle on metal surfaces, they create an electrolyte that causes the metal to oxidize quickly. Since the protective surface layer breaks down, the underlying metal is left exposed to deterioration, which can progress rapidly in coastal environments where salt-laden air is a constant presence.

Not all metal roofing materials respond to saltwater exposure in the same way. Aluminum tends to resist corrosion better than steel, while copper and zinc each have distinct reactions to coastal conditions. Understanding these differences is crucial for Tampa homeowners and property managers when selecting roofing materials that will stand up to the local climate.

The impact of saltwater on metal roofing extends beyond just surface rust, potentially affecting structural integrity, appearance, and overall performance. Recognizing the signs of saltwater damage early can save substantial repair costs down the road.

Signs Your Metal Roof is Suffering from Saltwater Damage

Identifying saltwater damage on your metal roof early can save Tampa homeowners significant repair costs and extend the life of their roofing investment. Regular inspections become especially important for properties located near Florida’s beautiful coastlines, where salt exposure is constant and often intense.

Early warning signs of saltwater corrosion include a chalky white powder residue that appears on the metal surface. This is actually salt that’s accumulated on the surface, and it’s one of the first signs that something is wrong. You may also notice patterns of discoloration, typically appearing as streaks or spots that differ from the original color of the roof. Small pits or dimples forming on the metal surface also indicate corrosion that has already begun breaking down the protective coating.

As damage progresses, more severe signs will emerge. These include visible rusting that spreads across larger areas and structural weakening where the metal begins to thin or even develop holes. Fastener failure is another common issue, as the screws and clips securing your roof panels may corrode faster than the panels themselves. The protective coating may also start to break down, appearing cracked, flaked, or peeled away from the metal substrate.

Property owners on the coast of Tampa should inspect their metal roofs at least twice a year, paying special attention after severe storms that may have carried additional salt spray onto the roof’s surface. Catching these symptoms early allows for targeted interventions that can prevent the need for a complete roof replacement.

The Coastal Distance Factor: How Proximity to Saltwater Impacts Deterioration

When it comes to metal roofing in Tampa and the surrounding coastal areas, location matters tremendously. The distance between your property and the shoreline directly influences how quickly saltwater corrosion affects your metal roof. Research shows that salt concentration in the air decreases significantly as you move inland, creating distinct areas where some metal roofs are more at risk than others.

Properties typically located within 500 feet of the shoreline experience the most aggressive forms of corrosion. In these areas, metal roofing may deteriorate up to 10 times faster than identical materials installed just a mile inland. Tampa homes situated 1,000 to 3,000 feet from saltwater often face moderate exposure, while properties beyond 1 to 2 miles generally experience minimal salt-related deterioration.

Even within the same neighborhood, microclimate variations can create dramatically different conditions for metal roofs. Tampa’s prevailing easterly winds can carry salt spray further inland, which corrodes one side of a structure while leaving another side relatively protected. Elevation plays a crucial role as well, since roofs on higher ground or tall buildings often capture more airborne salt particles than those in lower-lying areas.

Surrounding structures also influence salt deposit patterns. Buildings, trees, and other obstacles can either shield your roof from salt exposure or create tunneling effects that concentrate salt-laden winds.

Protective Metal Roof Coatings for Saltwater Environments

Metal roofs in coastal areas like Tampa need specialized protection to withstand the harsh effects of saltwater exposure. Marine-grade finishes and specialized coatings create essential barriers against the relentless assault of salt spray and chloride attack. These protective systems typically consist of multiple layers, starting with zinc or zinc-aluminum galvanization as the base layer, followed by primers designed specifically for coastal environments, and topped with high-performance paint systems containing corrosion inhibitors.

PVDF coatings, such as Kynar 500, represent the gold standard for saltwater protection, offering superior resistance to chalking, fading, and corrosion. These premium finishes maintain their protective qualities for 25 to 30 years in coastal settings. Silicone-modified polyester coatings provide a mid-range option with 15 to 20 years of effective protection. Acrylic coatings, while more affordable, typically require reapplication every 7 to 10 years to maintain their protective quality against saltwater exposure.

Tampa homeowners should note that it’s just as important to apply these coatings properly as it is to choose the right one for your roof. Professional installation ensures complete coverage and proper adhesion, maximizing the protective barrier. Regular maintenance, including gentle cleaning to remove salt deposits and prompt touch-up of any damaged areas, significantly extends the lifespan of these protective systems in our challenging Gulf Coast environment. With the right coating system and proper care, metal roofs can withstand decades of saltwater exposure while maintaining both functionality and appearance.

Essential Maintenance Practices for Metal Roofs on the Coast

Protecting your metal roof from saltwater damage requires a proactive maintenance approach, especially in coastal Tampa areas where salt exposure is a daily reality. Regular maintenance not only preserves your roof’s appearance but also significantly extends its service life, protecting your investment for years to come.

Cleaning protocols should include quarterly gentle washing with fresh water to remove salt deposits before they can begin to corrode the metal. For established salt residue, a mild solution of water and pH-neutral soap applied with a soft brush can effectively clean without damaging protective coatings. High-pressure washing should be avoided, as it may force water under seams and damage existing finishes. After cleaning, thorough rinsing prevents soap residue from attracting additional salt particles.

Coastal properties in Tampa require more frequent inspection schedules than buildings that are inland. Professional inspections every six months can identify early signs of saltwater damage before it requires you to make expensive repairs or replacements. These inspections should focus on checking fasteners and hardware, which often corrode faster than panels, examining seams and joints where salt can concentrate, and assessing coating integrity across the entire roofing surface.

Choosing the Right Metal Roof for A Coastal Tampa Property

When selecting a metal roofing system for coastal Tampa homes, material choice becomes critical to long-term performance and durability. Aluminum stands as the premier option for saltwater environments, since it’s naturally resistant to corrosion even without additional coatings. Its oxide layer self-repairs when scratched, providing continuous protection against salt exposure, and while initially more expensive, aluminum’s 50 to 60-year lifespan in coastal settings often justifies the investment.

Specialized marine-grade alloys offer another excellent choice for Tampa’s coastal properties. These engineered metals combine the strength of steel with enhanced corrosion resistance through precise formulas. Look for Galvalume, or similar products specifically rated for marine environments, which contain aluminum-zinc alloy coatings that provide up to 3x more protection against corrosion than standard galvanized steel.

Beyond material selection, certain specifications dramatically improve saltwater performance. First, ensure your roofing system uses marine-grade fasteners – standard screws can fail prematurely, compromising the entire roof. Second, verify that panel edges and cut ends receive proper sealing to prevent salt intrusion at vulnerable points. Finally, select systems with minimal seams or standing-seam designs that reduce potential water entry points.

Tampa homeowners should also consider the warranty carefully, as many standard metal roof warranties exclude or limit coverage in coastal zones. The right Tampa roofing contractor will help navigate these options to identify the optimal metal roofing system for your specific coastal exposure conditions.

Professional Solutions: When to Call Tampa Roofing Experts

While regular maintenance helps protect metal roofs in coastal environments, there are situations where professional help becomes necessary. Understanding when to transition from DIY approaches to expert assistance can save Tampa homeowners from escalating damage and more expensive repairs later.

Professional assessment services provide a complete evaluation of saltwater damage to metal roofing systems. These roofing experts use specialized tools to measure coating thickness, detect hidden corrosion, and identify structural weaknesses that may not be visible to untrained eyes. These detailed assessments help determine the true extent of saltwater damage and whether localized repairs will suffice or if more extensive solutions are required.

The decision between restoration and replacement involves several important factors. Qualified roofing contractors evaluate current damage levels, remaining roof lifespan, and the property’s level of exposure to coastal conditions. For metal roofs with limited corrosion concentrated in specific areas, professional restoration may extend service life significantly. This might include applying specialized marine-grade coatings, replacing damaged fasteners, or treating corroded sections to halt deterioration.

However, when saltwater damage has compromised structural integrity or when the roof is approaching the end of its expected lifespan, replacement with more saltwater-resistant materials often proves to be better financially in the long term. Tampa roofing professionals can recommend optimal systems designed specifically for Florida’s challenging coastal conditions, ensuring your new metal roof provides decades of reliable protection against saltwater corrosion.

Protect Your Coastal Roof with SouthShore Roofing & Exteriors

If your property is in a coastal area, understanding how saltwater affects metal roofs is important for maintaining the integrity and longevity of your own metal roofing system. At SouthShore Roofing & Exteriors, we specialize in providing robust solutions for metal roofs exposed to harsh saltwater environments.

Is your metal roof showing signs of saltwater damage? It’s time to act! Call us now at (813) 400-3329 for an expert assessment and tailored solutions that guard your roof against the relentless coastal elements. Trust SouthShore Roofing & Exteriors to deliver professional, durable protection for your metal roofing needs.