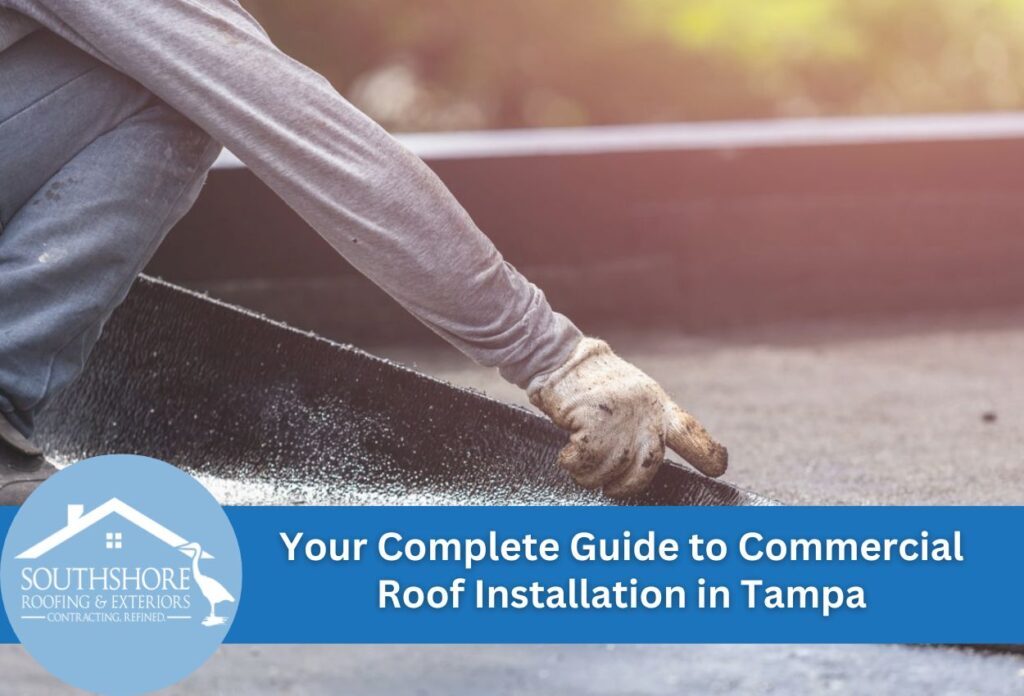

Your Complete Guide to Commercial Roof Installation in Tampa

Commercial roof installation is one of the most significant infrastructure investments a business owner will make. The process involves planning, material selection, and precise execution to ensure decades of reliable protection for commercial properties. Understanding this complex undertaking is essential when replacing aging roofing systems or constructing new facilities.

The commercial roof installation process differs substantially from residential projects due to scale, materials, and structural requirements. Commercial buildings typically feature flat or low-slope designs that need specialized roofing materials, such as roof membranes, and installation techniques.

Tampa’s sometimes harsh climate adds another layer of complexity to commercial roofing projects. Florida’s intense sun, frequent storms, and high humidity levels require careful consideration when selecting roofing materials and planning installation timelines. A flat roof installation must also account for proper drainage systems to handle heavy rainfall and wind resistance capable of withstanding hurricane-force conditions.

The commercial roof replacement timeline can vary significantly based on building size, weather conditions, and chosen materials, making planning crucial for minimizing business disruptions. For business owners planning commercial roof replacement projects, this guide provides everything you need to know about timelines, material options, and contractor selection.

The First Step: Choosing the Right Materials for Your Commercial Roof

Selecting a material is the first step in the commercial roof installation process. The most popular commercial roofing materials for flat and low-slope applications have different advantages in terms of durability and weather resistance. TPO (thermoplastic polyolefin) membranes provide excellent energy efficiency through their reflective white surface, while EPDM (ethylene propylene diene monomer) rubber membranes deliver proven longevity and flexibility. Modified bitumen systems combine the reliability of traditional asphalt with modern polymer enhancements for superior performance.

Installing commercial roof membranes requires understanding how material properties affect long-term performance in challenging environments. TPO membranes resist UV degradation and chemical exposure, while EPDM systems stay flexible through temperature fluctuations. Modified bitumen provides exceptional waterproofing capabilities and puncture resistance.

The flat roof installation steps vary significantly based on chosen materials, affecting both installation complexity and the project timeline. Each material requires specific preparation methods, adhesives, and seaming techniques that influence project duration and its final performance over time.

Essential Steps in the Commercial Roof Installation Process

The commercial roof installation process follows a specific steps that begins with thorough preparation and structural assessment. Industrial roofing contractors start by removing existing roofing materials through careful tear-off procedures that protect the underlying deck structure. This phase includes disposing of old materials and inspecting the roof deck for any damage or deterioration that requires repair before proceeding with the new installation.

Installing commercial roof membranes requires precise execution across multiple phases. Contractors begin by installing insulation boards and vapor barriers according to manufacturer specifications. The membrane installation follows specific installation steps, including proper seaming techniques and adhesive application. Quality control measures throughout this phase ensure membrane alignment, seam integrity, and sufficient drainage slope.

Safety protocols are non-negotiable during every stage of the commercial roof replacement. Professional contractors use fall protection systems, establish secure work zones, and maintain constant communication between crew members. Weather monitoring is also critical, as membrane installation requires specific temperature and wind conditions for optimal adhesion and curing.

The final inspection phase involves comprehensive testing of all seams, penetrations, and drainage systems. Contractors conduct flood testing in designated areas to verify waterproof integrity before project completion. Documentation of installation procedures, warranty information, and maintenance recommendations is given to property owners as part of the complete project records. This approach to commercial roof installation guarantees long-term performance and weather protection for commercial facilities.

Quality installation practices directly influence the system’s longevity and performance over decades of service. When installing commercial roof membranes, contractors create foundations that resist common failure points, including membrane separation, seam deterioration, and drainage problems. Professional installation techniques ensure optimal adhesion, appropriate thermal movement accommodation, and proper flashing integration that prevents premature system degradation.

Understanding Commercial Roof Membrane Installation

Commercial roof membrane installation represents the most critical phase of the roofing process, directly impacting long-term performance and weather protection. The three primary installation methods each offer specific advantages depending on building conditions and the commercial roofing materials selected.

Fully adhered systems create complete bonding between the membrane and substrate, providing maximum wind uplift resistance and structural integrity. Mechanically attached installations utilize specialized fasteners and plates to secure membranes to the roof deck. This method allows for thermal movement while maintaining secure attachment points throughout the membrane surface. Industrial roofing contractors often recommend this approach for buildings with structural limitations or when working with specific membrane types that perform best with mechanical attachment systems.

Ballasted systems rely on gravel or pavers to hold membranes in place. This installation technique works well for buildings with adequate structural capacity and minimal rooftop equipment. The ballast material protects the membrane from UV exposure while providing additional thermal mass for energy efficiency.

TPO systems typically require mechanically fastened or fully adhered installation methods, making them adaptable to various structural conditions. EPDM membranes offer versatility through ballasted, adhered, or mechanically attached installation options. Modified bitumen applications involve torch-applied or cold-adhesive techniques, each requiring specific expertise from industrial roofing contractors.

Proper membrane installation creates watertight seals that prevent common roofing problems, including ponding water and air infiltration. Professional contractors understand how drainage slopes and membrane tensioning eliminate water accumulation that can compromise system integrity. The flat roof installation also includes sealing around equipment and drainage components to maintain complete weather protection.

Timeline Expectations for Commercial Roofing Projects

Project duration for commercial roof installation varies significantly based on several factors that building owners must consider during planning phases. Building size represents the most obvious timeline influence, with larger facilities requiring proportionally longer installation periods. A 10,000 square foot warehouse typically requires different scheduling than a 50,000 square foot manufacturing facility, affecting both labor and the replacement timeline.

Weather conditions directly impact installation schedules, particularly when installing commercial roof membranes that require specific temperature and wind parameters for proper adhesion. Rain delays can extend project timelines by several days, while extreme temperatures may limit daily work windows. Industrial roofing contractors often build weather contingencies into project schedules to accommodate these variables without compromising installation quality.

The complexity of the roof structure adds another timeline variable that affects the commercial roof installation process. Buildings with multiple levels, extensive HVAC equipment, or structural modifications require additional preparation time and specialized installation techniques. The condition of existing decking materials influences tear-off duration, while the number of vents, skylights, and pipes on the roof affects installation complexity.

Business operations planning is essential for minimizing disruption during roof replacement projects. Scheduling installations during slower business periods helps reduce operational impact, while phased installation approaches allow continued facility use. Coordinating with industrial roofing contractors to establish clear work boundaries and access routes protects both workers and business activities. The flat roof installation can often accommodate partial building occupancy when carefully planned, allowing businesses to maintain essential operations throughout the project timeline.

Working with Professional Commercial Roofing Contractors

Selecting qualified industrial roofing contractors requires considering several essential credentials that ensure project success and legal compliance. Licensed contractors demonstrate their commitment to professional standards and possess the necessary permits to perform commercial roof installation work. Comprehensive insurance coverage protects property owners from liability during construction phases, while bonding provides financial security for project completion.

Local experience is invaluable when evaluating potential contractors. Contractors familiar with regional building codes understand permit requirements and inspection procedures that affect project timelines. Their knowledge of local climate conditions also influences material recommendations and installation techniques that optimize long-term performance.

Professional contractors should provide detailed explanations of their roofing techniques when asked about the commercial roof installation process. Quality contractors readily discuss their approach to membrane preparation, seaming techniques, and quality control measures. Their willingness to explain their flat roof installation steps demonstrates their technical expertise and overall transparency.

Warranty coverage and project management techniques separate experienced contractors from less qualified competitors. Contractors who offer warranties on materials and workmanship provide long-term protection for roofing investments. Established project management systems ensure clear communication throughout the commercial roof replacement, including progress updates, weather contingencies, and completion schedules. Professional contractors also keep documentation of completed commercial roofing projects, creating valuable records for future maintenance and warranty claims.

Ensuring Long-Term Success After Installation

Documentation and maintenance planning are the final steps after the commercial roof installation is complete. Contractors should provide comprehensive installation records that include material specifications, warranty details, and maintenance recommendations tailored to the specific commercial roofing system installed. These documents serve as essential references for future inspections and help property owners understand their coverage terms and maintenance obligations.

Regular maintenance from qualified contractors helps identify signs of issues before they need expensive repairs. Preventive maintenance programs typically include biannual inspections, drainage system cleaning, and membrane condition assessments that extend system life significantly beyond standard expectations. These proactive approaches often prevent the need for premature roof replacement while maintaining warranty compliance.

The commercial roof replacement timeline may be extended when installations follow manufacturer specifications and industry best practices compared to rushed work. Quality workmanship during initial installation creates systems that perform reliably for 20 to 30 years with appropriate maintenance, while poor installation practices can necessitate major repairs within just a few years of completion.

Ensure Your Tampa Business is Protected with a Durable Roof from SouthShore Roofing & Exteriors

Understanding the commercial roof installation process is crucial for every Tampa business owner. Selecting the right materials and following proper installation steps are the keys to a roof that stands the test of time. At SouthShore Roofing & Exteriors, we pride ourselves on our expertise in handling different types of commercial roofing materials and installation techniques tailored to Florida’s unique climate.

Whether you’re considering TPO, EPDM, or modified bitumen, our team ensures a seamless installation from start to finish. Don’t let the Florida weather dictate the lifespan of your commercial roof. Call us today at (813) 400-3329 to schedule a consultation and learn how we can help protect your investment with a professionally installed, high-quality roof that addresses all your business needs.